Design & manufacture of the FENDERTEX® Fender

DESIGN OF THE FENDER

The concept behind this textile fender was developed to reduce the space required for storage on board, while meeting a precise set of specifications:

-

Withstand extreme pressure and tensile stress, equal to or greater than existing products on the market.

-

Offer lighter weight for easier handling.

-

Provide an elegant look through the use of textile material.

-

Ensure resistance to UV rays thanks to solution-dyed yarn.

-

Prevent salt build-up thanks to its design.

-

Maintain its position on the hull with an ovoid shape created by reduction points in the outer cover.

-

Offer a range of shapes: cylindrical, spherical, and tubular.

This project was carried out in collaboration with nautical professionals, captains, and industrial and technical partners. We then joined INNOTEX at CETI (European Center for Innovative Textiles). After four years of research and development, we succeeded in creating a finished, tested, and market-ready high-quality product.

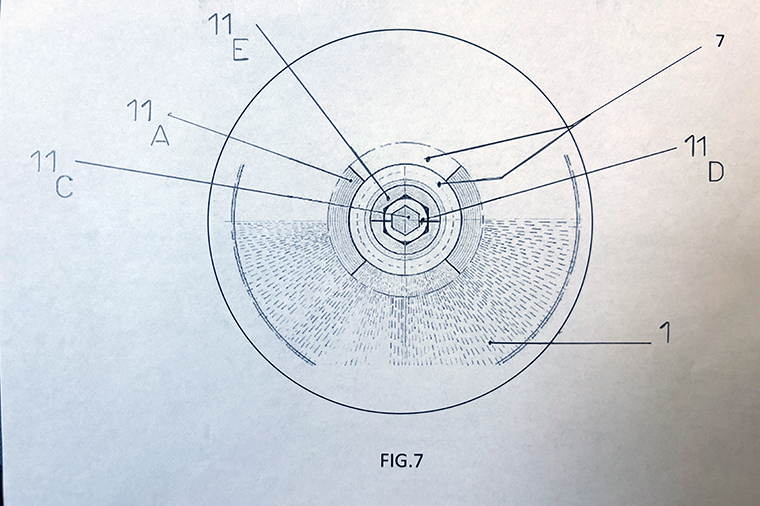

The technical design and performance of this fender, particularly its resistance to pressure and tensile stress, are protected by a worldwide patent.

This product is manufactured exclusively in France.

All FENDERTEX® fenders are guaranteed. In the event of an issue, please contact our customer service so the product can be returned for inspection and servicing.

The Manufacture of Fenders

Design of the inflation/deflation valve

Cutting inner bladder into strips.

Sewing the fenders in series.

Fendertex innovation: filling/draining valve attachment

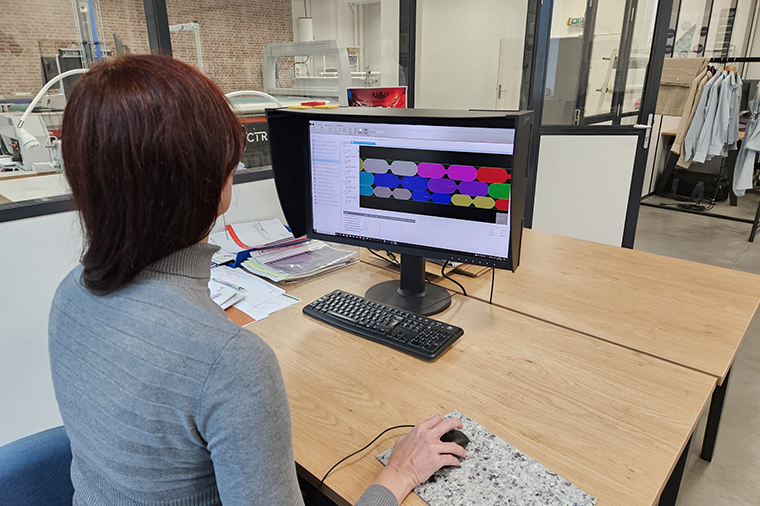

Use of technical yarns developed in our R&D offices.

Numerically controlled cutting table.

Seams on the fender.

Assembly and leak testing.

Tubular cover design.

Welding of inner bladders.

Sewing the collar.

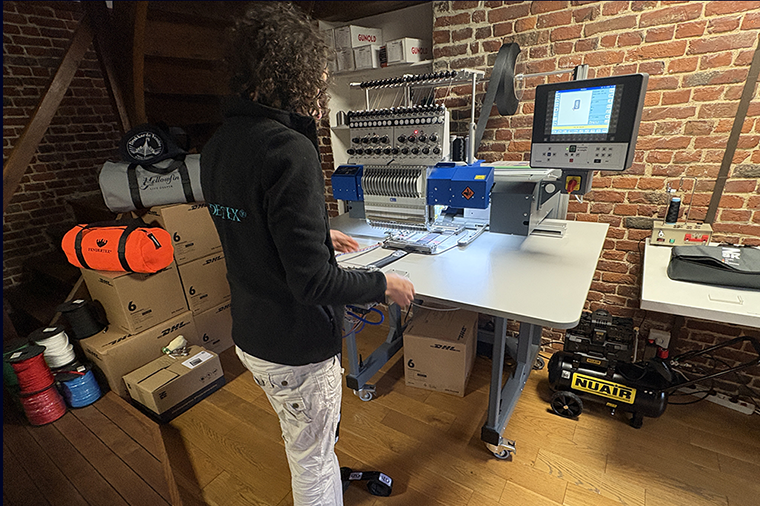

Embroidery on straps.